Infrastructure

Infrastructure

As leading plastic pipes manufacturers in India, we have been doing well in maintaining our reputation in this domain. Our in house research and development units have helped us with innovative technologies and facilities which are the requirements of the present system. The infrastructure includes a well equipped state-of–art facilities consisting of warehousing units, manufacturing units, packaging units and quality control units which are maintained by our skilled professionals

Our R & D Section

Research Section

Our research division is dedicated to pushing the boundaries of innovation in the piping industry. Led by a team of visionary engineers, scientists, and industry experts, we are committed to exploring new materials, technologies, and methodologies that drive the industry forward.

At the heart of our research efforts lies a commitment to sustainability. We recognize the importance of environmental stewardship and are dedicated to developing eco-friendly materials and processes that minimize our environmental footprint while maximizing the performance and durability of our CPVC pipes.

Innovation is the driving force behind everything we do. Our research teams are constantly exploring new materials and technologies to enhance the performance, durability, and versatility of our CPVC pipes. From advanced polymer formulations to novel manufacturing processes, we are always pushing the boundaries of what’s possible in CPVC piping technology.

At the heart of our research efforts lies a commitment to sustainability. We recognize the importance of environmental stewardship and are dedicated to developing eco-friendly materials and processes that minimize our environmental footprint while maximizing the performance and durability of our CPVC pipes.

Innovation is the driving force behind everything we do. Our research teams are constantly exploring new materials and technologies to enhance the performance, durability, and versatility of our CPVC pipes. From advanced polymer formulations to novel manufacturing processes, we are always pushing the boundaries of what’s possible in CPVC piping technology.

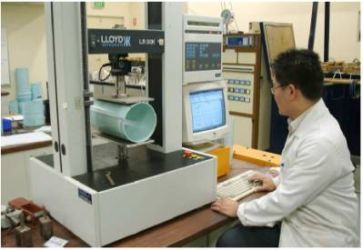

Testing Equipments

we showcase the advanced tools and technologies that enable us to ensure the quality, durability, and performance of our CPVC piping solutions.

Our testing equipment is at the forefront of industry standards, meticulously selected to conduct a wide range of tests that validate the integrity and reliability of our CPVC pipes. From material composition analysis to performance testing under various conditions, our equipment is designed to provide accurate and reliable results that meet and exceed industry requirements. Among our testing equipment, you will find:

✓ Material Composition Analyzers

✓ Pressure and Stress Testing Machines

✓ Temperature Control Chambers

✓ Dimensional Measurement Tools

✓ Chemical Resistance Testers

✓ UV Exposure Chambers

Our testing equipment is at the forefront of industry standards, meticulously selected to conduct a wide range of tests that validate the integrity and reliability of our CPVC pipes. From material composition analysis to performance testing under various conditions, our equipment is designed to provide accurate and reliable results that meet and exceed industry requirements. Among our testing equipment, you will find:

✓ Material Composition Analyzers

✓ Pressure and Stress Testing Machines

✓ Temperature Control Chambers

✓ Dimensional Measurement Tools

✓ Chemical Resistance Testers

✓ UV Exposure Chambers

Testing Laboratory

Our testing laboratory serves as the epicenter of innovation and quality assurance, where cutting-edge technologies meet rigorous analysis to ensure that our CPVC piping solutions exceed industry standards.

Equipped with state-of-the-art equipment and manned by a team of skilled technicians and scientists, our laboratory conducts a wide range of tests to evaluate the performance, durability, and safety of our CPVC pipes. From material composition analysis to pressure and stress testing, every aspect of our products undergoes meticulous scrutiny to ensure optimal performance in real-world applications.

Transparency and accountability are core values at Anlon. We welcome our customers to visit our testing laboratory and witness our processes firsthand. By opening our doors to scrutiny, we aim to build trust and confidence in the quality and reliability of our CPVC piping solutions.

When you choose Anlon, you can trust that our products have been rigorously tested and proven to deliver exceptional performance and durability. Welcome to our testing laboratory, where innovation meets excellence, and quality is our top priority.

Equipped with state-of-the-art equipment and manned by a team of skilled technicians and scientists, our laboratory conducts a wide range of tests to evaluate the performance, durability, and safety of our CPVC pipes. From material composition analysis to pressure and stress testing, every aspect of our products undergoes meticulous scrutiny to ensure optimal performance in real-world applications.

Transparency and accountability are core values at Anlon. We welcome our customers to visit our testing laboratory and witness our processes firsthand. By opening our doors to scrutiny, we aim to build trust and confidence in the quality and reliability of our CPVC piping solutions.

When you choose Anlon, you can trust that our products have been rigorously tested and proven to deliver exceptional performance and durability. Welcome to our testing laboratory, where innovation meets excellence, and quality is our top priority.

QC- Check

we demonstrate our unwavering commitment to ensuring the quality, durability, and reliability of our CPVC piping solutions.

Quality control is an integral part of our R&D process, and our QC checks are designed to uphold the highest standards at every stage of production. From raw materials to finished products, every component of our CPVC pipes undergoes meticulous scrutiny to ensure consistency and performance excellence.

Our QC checks encompass a comprehensive range of tests and inspections, including:

✓ Material Inspection

✓ Dimensional Accuracy

✓ Visual Inspection

✓ Pressure Testing

✓ Chemical Resistance Testing

✓ Performance Evaluation

Quality control is an integral part of our R&D process, and our QC checks are designed to uphold the highest standards at every stage of production. From raw materials to finished products, every component of our CPVC pipes undergoes meticulous scrutiny to ensure consistency and performance excellence.

Our QC checks encompass a comprehensive range of tests and inspections, including:

✓ Material Inspection

✓ Dimensional Accuracy

✓ Visual Inspection

✓ Pressure Testing

✓ Chemical Resistance Testing

✓ Performance Evaluation

About Us

ANLON Pipes takes this opportunity to introduce itself as a Leading Manufacturer and exporter of cPVC Pipes. We are supplying our products to our reputed clients. We have installed the latest machinery and equipment to produce various sizes and capacities of pipes.

Support

© 2024 ANLON PIPES. ALL RIGHTS RESERVED

WhatsApp us